Home > Products > Metal & Products > Steel Pipe & Tube > Preferential Supply High Quality Steel Tube/ Hollow Bar/ Seamless Steel Pipe/ 1010 Seamless Steel Tube Pipe

Preferential Supply High Quality Steel Tube/ Hollow Bar/ Seamless Steel Pipe/ 1010 Seamless Steel Tube Pipe

seamless pipes grades and production methods1. Round bar making Hollow Bar according to customer's demanded material to produce the round bar, then making annealled heat treatment, then drill the hole as customer demanded inner diameter into the round bar, round bar piercing, making rough hole......

Send Inquiry

Product Description

seamless pipes grades and production methods

1. Round bar making Hollow Bar

according to customer's demanded material to produce the round bar, then making annealled heat treatment, then drill the hole as customer demanded inner diameter into the round bar, round bar piercing, making rough hole, then make precision processing to make outer diameter and inner diameter as requested. Any size hollow bar can be produced as demanded.

Tolerance for hollow round bar, forged round bar drilling hole hollow bar ASME SA530

| Type | Outer diameter(inner diameter) | Allowed tolerance | Wall thickness allowed tolerance |

Outer diameter | ≥219-457.2mm | -0.8 - +2.4mm | -0.8 - +4.0mm |

| >457.2-660.4mm | -0.8 - +3.2mm | ||

| >660.4-863.6mm | -0.8 - +4.0mm | ||

| >863.6mm | -0.8 - +4.8mm | ||

| Inner diameter | All size | -1.6- 0mm | 0 - +3.2mm |

length tolerance -0 - +50mm

Round bar making Hollow bar cost is high

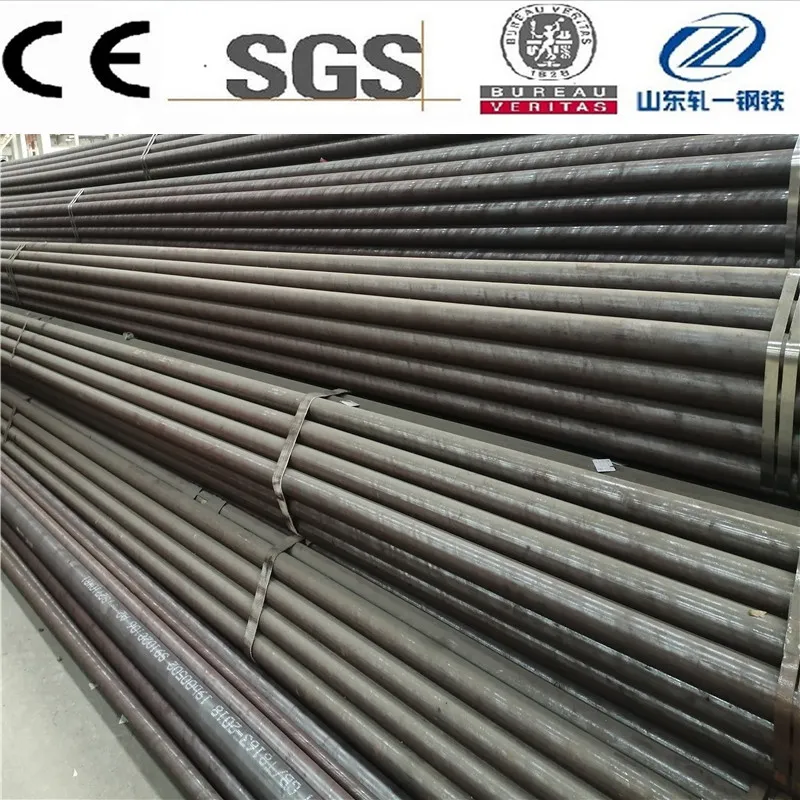

2. Hot rolled Hollow Bar

using hot rolled steel pipe billet to make heating and piercing, elongating, sizing and stranghtening, cooling, finally hollow bars finished, this is the type most commonly used. Because it is hot rolled, so cost is lowest, but it is suit for large quantity, for small quantity, have to make cold drawn or round bar piercing. size: outer diameter 32mm- 499mm, wall thickness 4mm- 80mm

3. Cold drawn Hollow Bar

for outer diameter not over than 63.5mm, small size hollow bar, when demanded quantity is under 5 tons, usually make cold drawn hollow bar, using larger size hot rolled hollow bar to draw to the size demanded.

some size can be finished only by one time drawing, but some other sizes might need twice or three times to finish drawing, it takes time, so the cost is higher.

cold drawn size outer diameter 32mm- 63.5mm

4. Hot- expanding Hollow Bar

For hollow bar sizes are special, not common sizes, have to use smaller thick wall hollow bar to hot expand to be larger size hollow bar, but the technical property for hot-expanded hollow bar will be lower than the original hollow bar. Size: outer diameter over 356mm.

the seamless pipe grades can be supplied

Seamless Steel pipe grades

| Descriptions | Grades |

| Structural pipe | 20# 35# 45# Q345B, 16Mn, Q345B-E, 20Mn2, 25Mn, 30Mn2, 40Mn2, 45Mn2 SAE1018, SAE1020, SAE1518, SAE1045. |

| Liquid pipe | 20# q295b-e, q345b-e |

| High pressure boiler tube | 20G 15MnG 20MnG 15CrMoG, 12Cr1MoVG St35.8, sa106b, sa106c, sa210a, sa210c, A333P2, A333P11, A33P12, A333P22, A33P36, A333P91, A333P92, A335T2, A335T11, A335T12, A335T22, A335T91, A335T23, A335T9 |

| Pipeline | API SPEC 5L, X42, X52, X60, X65,X70,X80 ASTMA53, ASTM A106, ASTM A333, BS301, BS3602, BS3603, BS3604, PSL1, PSL2, DNV-OS-F101, CSA-Z245 |

| Alloy pipe | 4140, 42CrMo, 32CrMo, 15CrMo, |

| Packing | Black paint, Varnish painting, Tarpaulin packing |

| End | Common round end, beveled. |

| Processing | Galvanizing; cutting; making thread outside the pipe; Machining. |

| outer diameter | 16mm- 800mm |

| wall thickness | 4mm- 80mm |

the seamless pipes stock detail

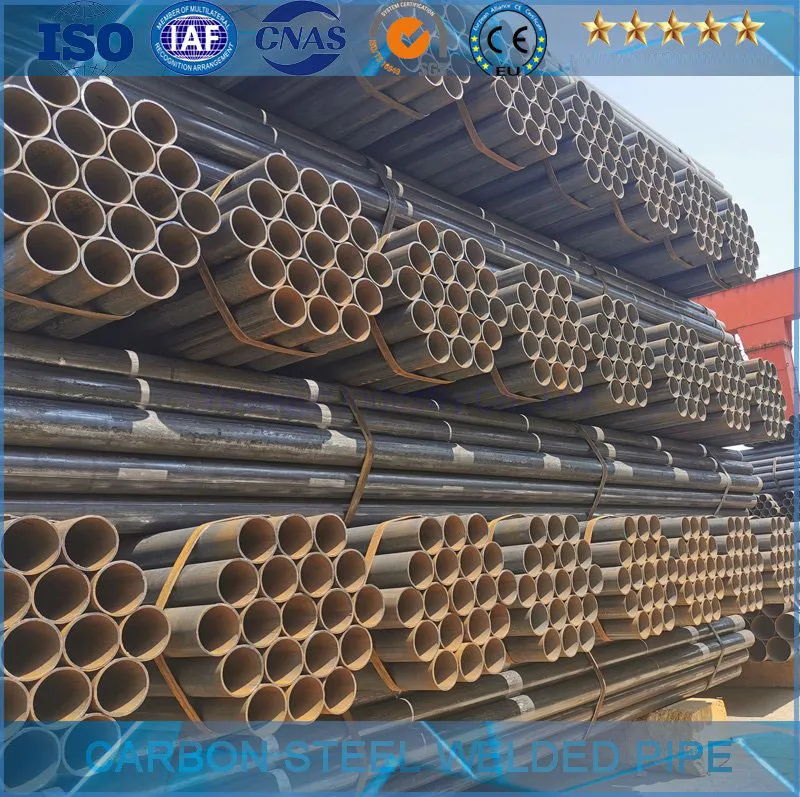

seamless steel pipes containers loading

steel pipes bulk vessel packing and loading

seamless pipes processing and fabrication

company introduction:

Tianjin Emerson Commercial and Trade co., Ltd located in Tianjin the largest seaport in north of China, has more than 10 years of experience in Iron and Steel materials, has large stock for steel raw materials. Tianjin Emerson products category: hot rolled steel plate and steel sheet, medium thick steel plate, stainless steel sheet and plate, galvanized steel sheet, and checkered steel sheet and plate; hot rolled steel coils, cold rolled steel coil, galvanized steel coil and stainless steel coils; seamless steel pipe, welded steel pipe, hollow bar, galvanized steel pipe, square pipe, rectangular steel pipe, and stainless steel pipes; steel bar, hot rolled steel bar, forged bar, rebar, deformed bar and other steel profiles. Except the steel raw materials, Tianjin Emerson can make steel fabrication and processing on steel raw materials: sheet metal fabrication, steel sheet laser cutting, steel sheet CNC flame cutting, steel sheet waterjet cutting, steel products welding and machining; make steel structure, and can make all types of steel parts or equipment by drawings. Emerson supplies good service for customer, good quality products, fast delivery, and good after-sale service, Tianjin Emerson hopes to build good cooperation with everyone interested.

We are a dynamic and dependable company. You can count on us to supply the right grade and the right size at the right price - delivered right on time, every time. Our innovative approach means you get the benefit of state-of-the-art technology coupled with personal professional service. The result is a business partner striving to meet your needs to help your business grow.

WHY CHOOSE US:

good quality! fast delivery time! good after-sale service

looking forward to your kind contact

Related Category

Steel Pipe & Tube

Steel Coil & Strip

Steel Sheet & Plate

Stainless Steel

Aluminum

Copper

Alloy

Tungsten

Titanium

Iron & Products

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.