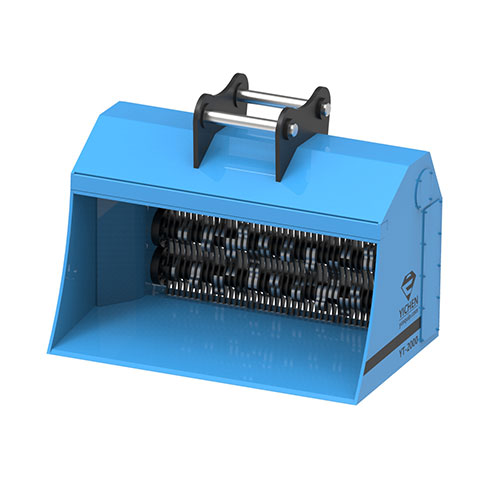

Screening Bucket

A screening bucket is a specialized attachment that can be mounted on an excavator, loader, or other construction machinery. It is used for separating and sorting different materials, such as soil, rocks, debris, and other aggregates. The screening bucket consists of a rotating drum or basket with s......

Send Inquiry

Product Description

A screening bucket is a specialized attachment that can be mounted on an excavator, loader, or other construction machinery. It is used for separating and sorting different materials, such as soil, rocks, debris, and other aggregates. The screening bucket consists of a rotating drum or basket with screening panels or grids, allowing the materials to be screened and sorted based on size or specific criteria. Here are some key features and considerations related to screening buckets:

1. Versatility: Screening buckets are versatile attachments that can be used in a variety of applications, including construction, landscaping, mining, recycling, and agriculture. They are commonly used for separating soil from stones, removing debris and contaminants, or sorting different types of materials.

2. Screening Mechanism: The screening bucket contains a rotating drum or basket with screening panels or grids. The size and spacing of the panels or grids can be customized to achieve the desired screening results. The rotation of the drum or basket allows the materials to be sifted and separated based on their size or specific characteristics.

3. Efficient Sorting: Screening buckets facilitate the efficient sorting of materials. The larger particles or objects are retained on the screening panels, while the smaller particles pass through and are discharged. This allows for the separation of different sizes or types of materials, helping to improve efficiency in various applications.

4. Different Screening Options: Depending on the requirements of the job, screening buckets can be equipped with various types of screening panels or grids. These may include mesh screens, punched plates, or grizzly bars. The selection of the appropriate screening option depends on the nature of the materials being processed and the desired outcome.

5. Quick Attachment and Operation: Screening buckets are designed for quick attachment and detachment to construction machinery. They can be easily mounted on excavators, loaders, or other compatible equipment using a coupler or quick hitch system. Once attached, the screening bucket is operated by the machinery's hydraulic system, allowing for efficient screening and sorting of materials.

6. Size and Capacity: Screening buckets come in various sizes and capacities to suit different machines and applications. The size of the screening bucket should be selected based on the capabilities of the host machine and the volume of materials to be processed.

7. Maintenance and Cleaning: Like any equipment, screening buckets require regular maintenance to ensure optimal performance. This may include cleaning the screening panels, inspecting and replacing worn parts, and lubricating moving components. Following the manufacturer's maintenance guidelines is essential for the longevity and reliable operation of the screening bucket.

Screening buckets provide an efficient and cost-effective solution for material separation and sorting in construction and other industries. They offer increased productivity, reduced manual labor, and the ability to recycle or reuse materials on-site. The specific design and capabilities of screening buckets may vary among manufacturers, so it's important to choose a reputable brand and model that meets your specific screening needs.